Water Drainage Sheet Extrusion Line

Water Drainage Sheet Extrusion Line Performance & Advantages

Water Drainage Sheet: It is made of HDPE material, the outer figure is of cone salient, functions of draining water and storing water, features of high stiffness and pressure resistance.

Advantages: Traditional drainage water prefers brick tile and cobblestone for draining water. Water drainage sheet is used for replacing the traditional method to save time, energy, investment, and reduce the load of the building.

The plastic drainage board is made of polystyrene (HIPS) or polyethylene (HDPE), which is punched into conical bosses or stiffener convex points (or hollow cylindrical porous).

The traditional drainage method uses masonry tiles as the filter layer and uses more pebbles or crushed stones as the filter layer to drain water to the location. Nowadays, the drainage board is used to replace the pebble filter layer to drain water, which saves time and effort. It also saves energy, saves investment, and reduces the load on buildings.

A well-functioning drainage system with a drainage board plays an important role in the construction period of civil works and the normal use and life of structures. The surface of the drainage board and the porous pipe form an effective drainage system, thus forming a system with water seepage, water storage, and drainage functions.

Water Drainage Application

Plastic drainage boards are mainly used in the backflow drainage of highways, railway subgrades, dams, and protective layers, municipal engineering, road foundation subway tunnels, waste landfill sites, and surface water inversion.

Construction engineering: the upper or lower layer of the building foundation, the wall of the basement, the roof greening, drainage, seepage prevention, and insulation layer, etc.

Greening project: construction projects such as garage roof greening, roof garden, football field, golf course, bathing field, and so on.

The drainage board is made of PP injection molding. It is a new type of geotechnical material that integrates drainage and water storage functions. It also has multiple functions such as water storage, drainage, ventilation, moisture retention, heat insulation, and prevention of plant roots from damaging the concrete structure.

When combined with geotextile, it can prevent fine particles from clogging the water storage tank and drainage channel, and keep the drainage and air circulation smooth. It is widely used in landscaping projects.

Commonly used drainage boards in construction are: plastic drainage boards, storage drainage boards, coiled drainage boards, anti-seepage drainage boards, composite drainage boards, three-dimensional drainage boards, sheet drainage boards, etc.

Water Drainage Sheet Extrusion Line Main Technical Parameter

| Model | Products width | Products thickness | Capacity |

| JWS-120 | 2000-3000mm | 0.5-3.0mm | 600kg/h |

| JWS-150 | 2000-5000mm | 0.5-3.0mm | 1000kg/h |

FAQ

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW.

● Terms of Payment: LC, T/T.

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months.

● Number of Foreign Trading Staff:>50 People.

Yes, We own 5 manufacturing bases and sales center in Shanghai, Suzhou, Changzhou, Zhou Shan, Dongguan China.

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo. After more than 40 years development.

JWELL is one of the biggest extrusion machine supplier in China with 300design&test engineer, 3000 employees.

Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

Our machines taking the European standards and follow the Germany type of business, we cooperation with International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously imports over 1000 international first-class high precision processing equipment such as multistage machining centers, CNC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification, IS09001 and 2008 quality management system. And we have 12 months quality warranty time. We testing the machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical innovation or improvements for your future purchasing plan.

We produce more than 2000 advanced extrusion lines every year world wide.

We can send the small spare parts by air express for urgent matter. And the complete production line by sea to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing engineers traveling world wide. Any cases would be responded with prompt solutions. We provide training, testing, operation and maintenance service for a life time.

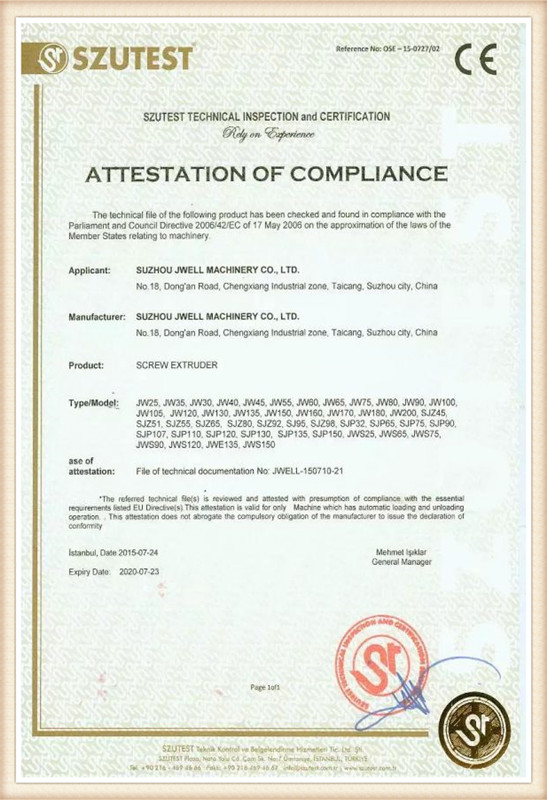

Certificates

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: Other

Design, Development, Manufacture And Sales Of Intellectual Property Rights Management For Plastic Machine

2016-06-14 ~ 2019-06-13

Certified By: Other

Design, Development, Manufacture And Sales Of Plastic Pipe And Sheet Extrusion Production Line

2018-11-20 ~ 2021-11-19

Certified By: Quality Austria Training, Certification and Evaluation Ltd.

Plastic Extrusion Line

2010-01-29 ~